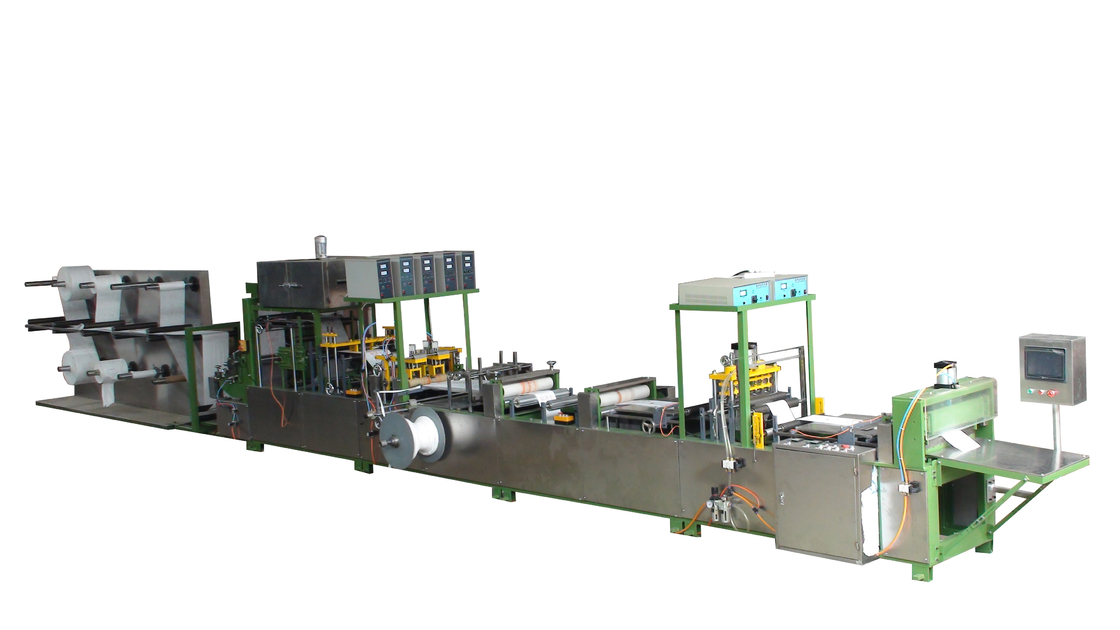

Vacuum Cleaner Filter Bag Making Machine , Non Woven Bags Manufacturing Machine

Description:

The equipment can produce non-woven bags and roll the mouth edge of non-woven filter plug. Equipment with full servo system and printing system, photoelectric probe tracking, ensure the rolling mouth, no cumulative error. The company's production has to Shanghai, Jiangsu, Zhejiang and foreign manufacturers to develop different specifications, different production processes of non-woven fabric filter bag machine, more than 20 Taiwan, accumulated a wealth of production experience, has reached the highest level of technology. Welcome field trips.

The company's production has to Shanghai, Jiangsu, Zhejiang and foreign manufacturers to develop different specifications, different production processes of non-woven fabric filter bag machine, 30 sets, has accumulated rich experience in production, the latest research and development of servo with communication of non-woven fabric air filter standby, has reached the highest level of technology. Welcome field trips.

Specification:

|

Model No.

|

Qx-r500

|

|

Slitting Device

|

Shear Type Round Knives

|

|

Perforating Device

|

Spiral Perforating

|

|

Rewinding Device

|

Special Cylinder Pressing

|

|

Slitting Material

|

Spun-Lace Nonwoven,Needle-Punched Nonwoven,Melt-Blown Nonwoven,Hot Sealing Nonwoven,Spun-Bond

Nonwoven,Textile Material,Paper,Etc

|

|

Equipment size

|

L13.8M, W1.0M

|

|

Motor

|

Stepping Motor

|

|

Parameter-Setting

|

Man-Machine Interface

|

|

Production Speed

|

30-70meter/Min

|

|

Air Compressor

|

Provided By Yourself

|

|

Packing Size

|

Depending On The Configuration

|

|

Power

|

380v 50hz 7.5kw

|

|

Weight

|

About 3800kg

|

Features:

1, Production equipment required: roll the mouth bags, trimming neat. Smooth without burrs. Fastness.

2, The device is equipped with adjustable automatic rolling device 1 sets.

3, Equipment tail with 10 groups of unilateral stent material feeding device, material on the computer the maximum width 460mm; with mechanical tension device, and the gas distribution up axis unwinding.

4, Equipment with automatic identity material conveying system, and is equipped with in the folded edge of the molding system, with stainless steel in mold a set, specifications on demand. Folding roller, 2 pairs, in order to insert the folded edge edge shape fully crushed.

5, Production rate: the normal production of 30-70 per minute (according to the weight of the material and the size of the bag, bag shape, etc.).

6, Equipped with automatic winding device for winding around the waste, waste piled up.

7, Bag size can be adjusted. Flat bag width in 420mm. In a certain range, the length can be adjusted by the touch screen and the servo control system.

8, The device is equipped with 5+2 sets of high power ultrasonic system (including 2 sets of 15K for Guangdong, 5 sets of 20K for the production of Changzhou). All the equipment used in the transmission of the guide roller are used (Shanghai) the best domestic hard oxide to strengthen the aluminum roll transport, equipment design for the 4 groups of ultrasonic rolling, cutting independent control device (using linear bearing system to control the adjustment of the mold).

9, All the equipment used in the production of equipment, the use of imported special materials, indentation patterns are used in special process computer engraving processing (pattern can be customized according to the requirements).

10, The whole set of equipment size: length 13.8 meters, width 1 meters. Weight about 3.8 t

11, Equipment and electrical equipment with 4 sets of servo motor and anti - interference system, PLC, touch screen, import photoelectric tracking system joint control operation (servo motor are Taiwan joint venture "new" brand). And the design of the control system (such as the loss of 1 or more devices automatically stop, so as not to reduce product loss);

12 And equipment operating process, raw material put volume, pattern and color automatic printing, photoelectric tracking, rolling, on both sides of the adhesive, trimming, photoelectric tracking cross hot bonding, photoelectric tracking cutting, product output.

13, Equipment total power 7.5kw, rated voltage 220V

14,The machine frame by GB molding (channel 12) steel production, surface antirust paint processing, machine frame is welded and precise size, stent of appropriate reinforcement, belt wheel, bevel gear and all transmission part, the accuracy of center, the main gear points processing, convenient for adjusting the gap. To ensure the stable operation of the machine.

15. Standard fasteners used in all hexagonal screw and high-quality domestic 45# steel. On the finished product is easy to cause the influence of parts are all made of stainless steel materials. Machine all plating are divided into secondary electroplating, smoothness is good to ensure smoothness for all the parts of the machine, anti rust resistant degree, equipment II years will not rust, delamination.

16, Equipment is equipped with a monochrome printing system 16 sets, to ensure that the production of printing bags and non printing pattern bag (ultrasonic die roll, ultrasonic sealing and cold cut off the distance error of 2 mm or less, no accumulated error), equipment installation servo system, photoelectric probe tracking, guarantee roll, sealing and cut off the length error within 2 mm, no cumulative error.

17, Ultrasonic mould and rolling and edge mould around mobile are produced by adjusting screw hand about the width, and handle rapid fixed position.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!